Roof

Roof is one of the areas of the building where our company provides Waterproofing services.

Our services include:

1. Supply: We supply the highest German Quality materials of Koster Company. (For details about our Materials Technical Datasheets, please see below)

2. Implementation: Our achievement are supervised by a Certified Engineer of Koster company. They are implemented by Allngar Professional and Experienced Staff.

3. Warranty: Our services warranty long term solutions ( for 25 to 50 years ).

You will save money with us because your Roof will not need maintenance in the future.

Our services are perfectly in harmony with modern art on Engineering and they are environmental friendly.

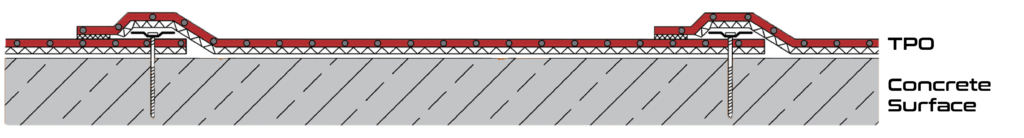

Waterproofing by Using TPO:

Thermoplastic Polyolefin (TPO) is a protective layer produced by a

mixture of polyolefins including mineral glasses to make it

stronger.

This layer is used to prevent the passage of water in four various

ways depending on the area and the purpose

(details provided in chapter five).

Benefits of Thermoplastic Polyolefin(TPO)

• Is a membrane material, it is not liquid as paint. It is similar to a strong plastic sheet.

• Due to its capacity of elasticity, TPO

adapts itself to the roof movement.

• It is UV resistant.

• It resists strong climate change and chemical materials.

• Given it’s strength, TPO cannot be torn by tree roots.

• It guarantees the safety of your roof avoiding any cracks permanently.

• Excellent for health, clean water, earth, animals and plants.

• TPO is environmentally friendly and recyclable.

• TPO resists hot weather till 100-120 degree.

• TOP has a light weight; it can be installed easily.

• TPO has drinking water certificate.

• Given its strength, TPO saves you money as it lasts for long time, it stays intact for more than 30 years.

Thermoplastic Polyolefin/TPO placement:

1. Roof

2. Water Tank

3. Swimming Pool

4. Basement

Roof insulation Types:

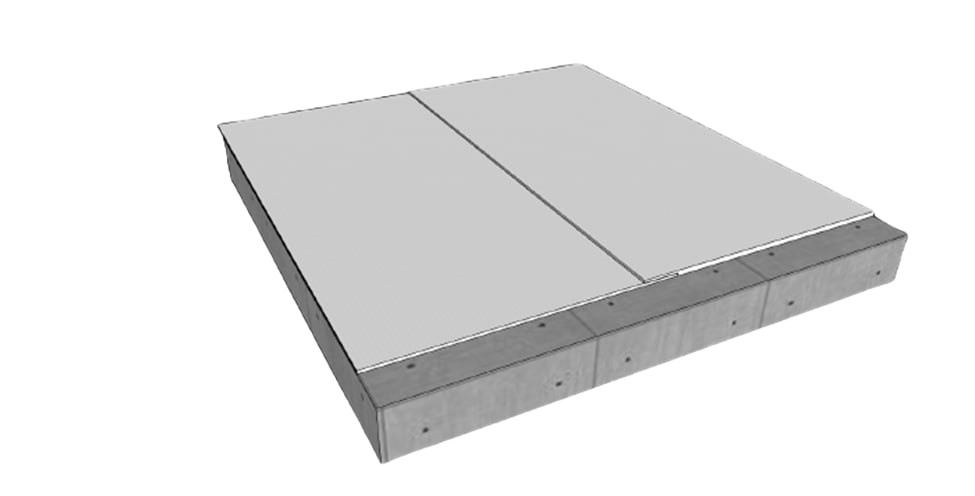

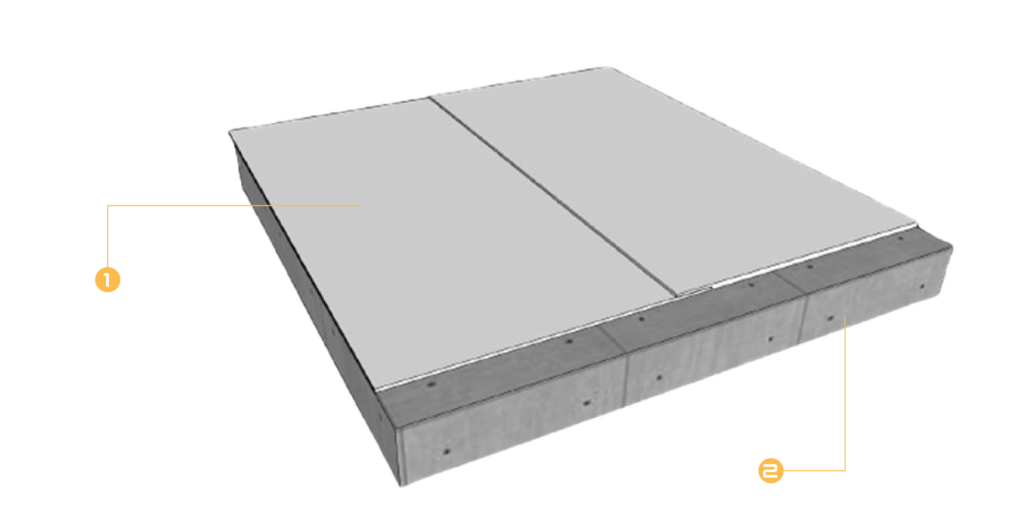

1. Waterproofing

Procedures

1. Cleaning and grinding the surface.

2. Firstly, laying the TPO layer on the surface. Then, tightening the TPO with screws and plugs. Later, welding the TPO edges with a specialized Swiss made machine (Leister 300).

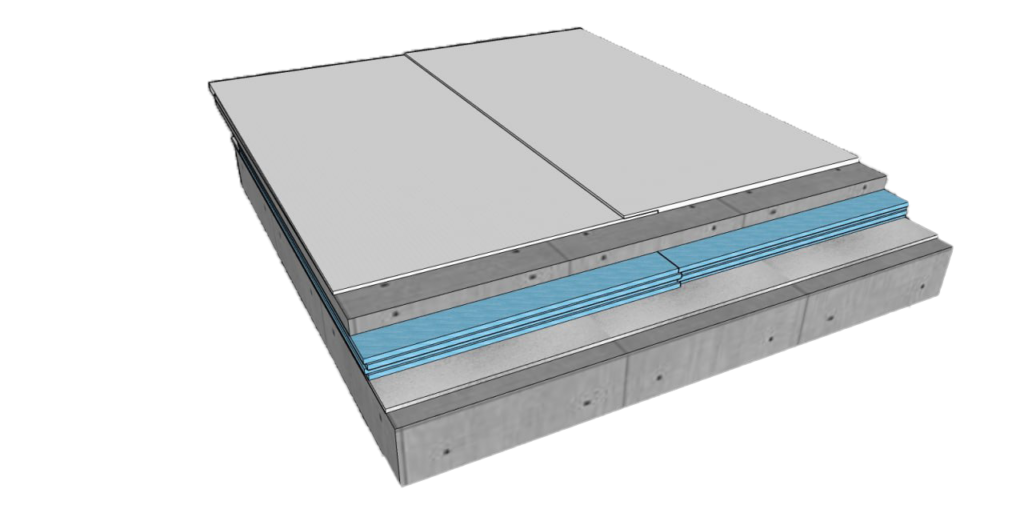

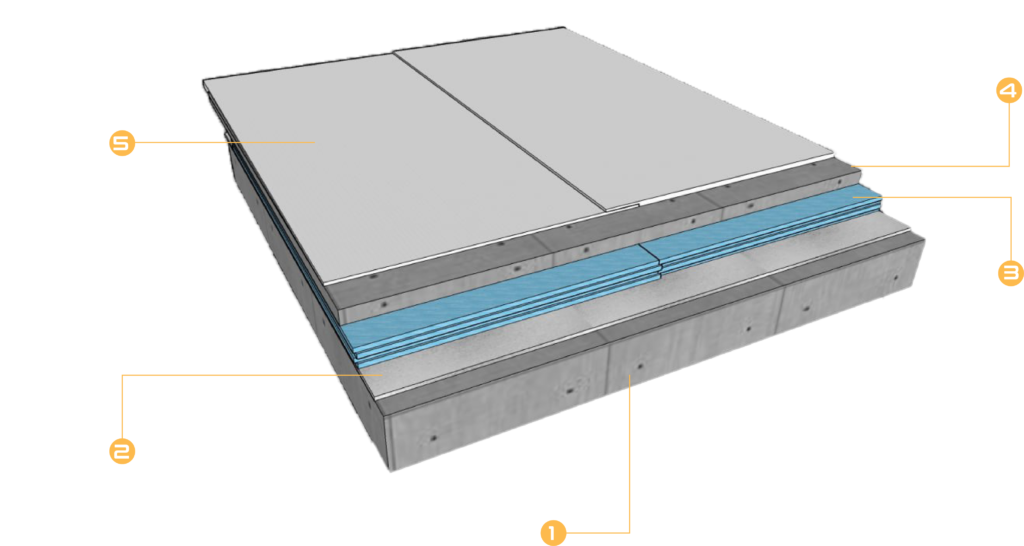

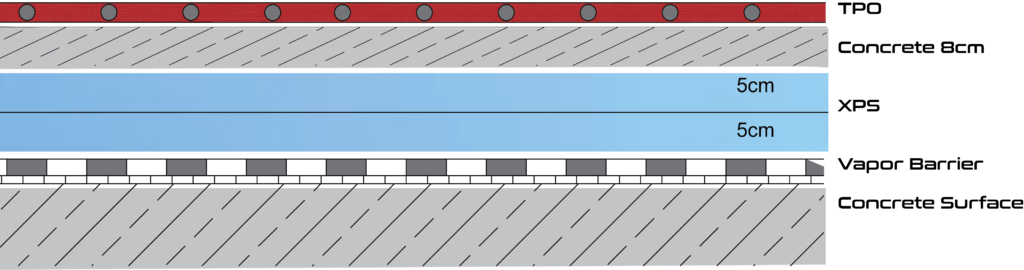

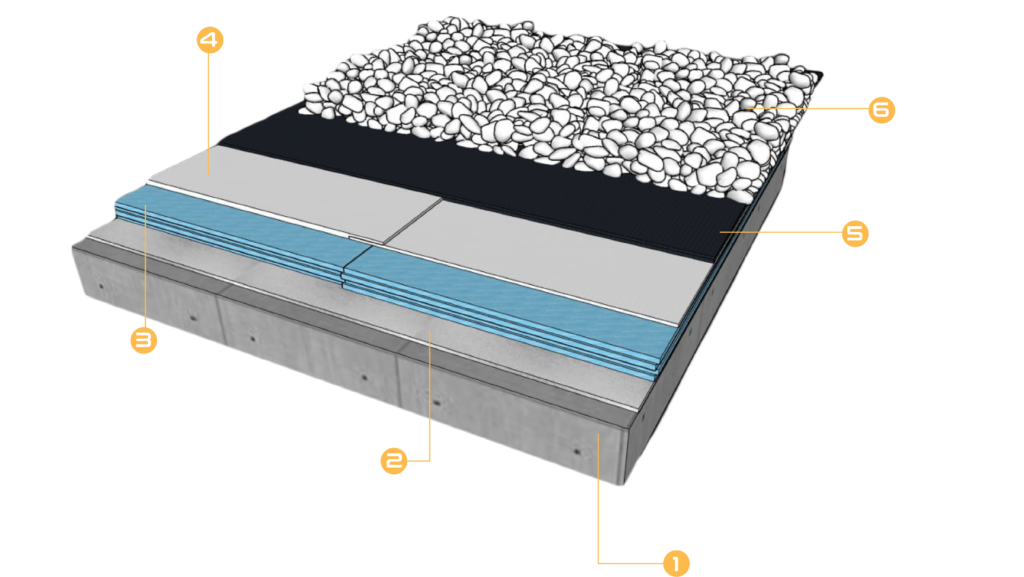

2. Waterproofing, Cold & Heat by Using XPS

Procedures

1. Cleaning and grinding the surface.

2. Laying vapor Barrier.

3. Installing 10 cm of XPS (two layers, 5 cm each layer).

4. Installing 8 cm of concrete layer including BRC iron bars.

5. Firstly, laying the TPO layer on the surface. Then, tightening the TPO with screws and plugs.

6. Later, welding the TPO edges with a specialized Swiss made machine (Leister 300).

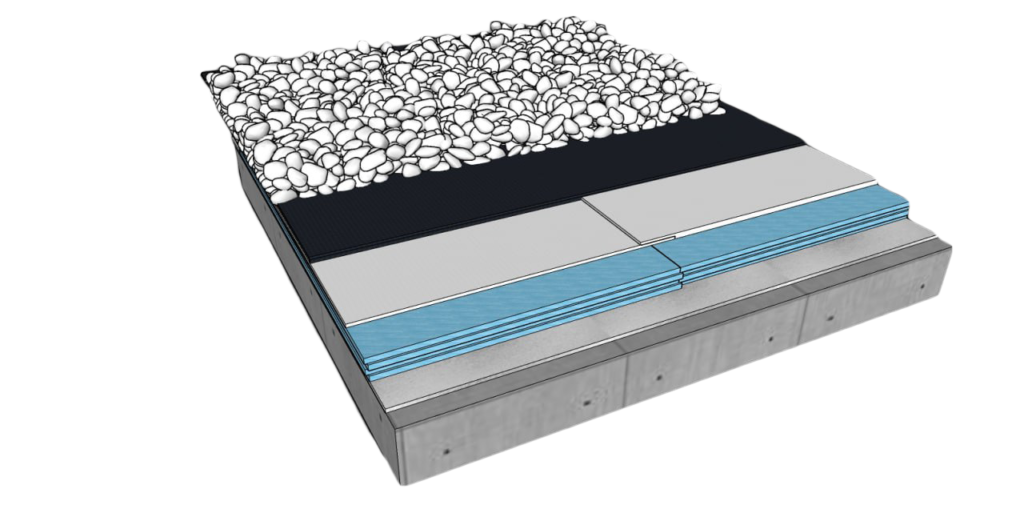

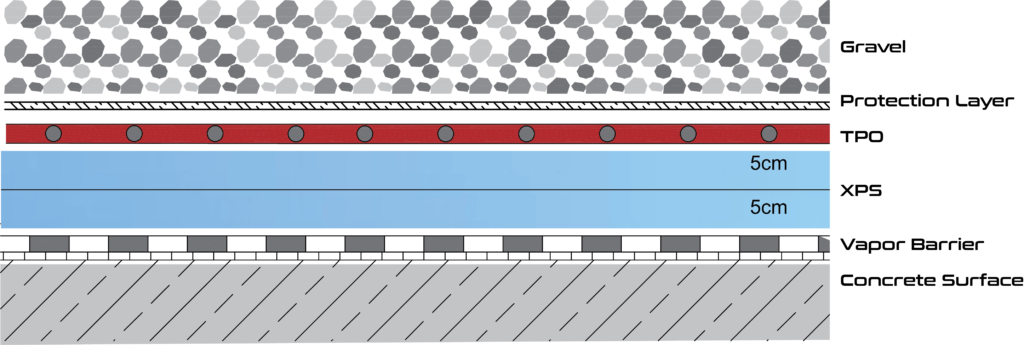

3. Waterproofing, Cold & Heat by Using XPS and Loose-laid

Procedures

1. Cleaning and grinding the surface.

2. Laying vapor Barrier.

3. Installing 10 cm of XPS (two layers, 5 cm each layer).

4. Firstly, laying the TPO layer on the surface.

5. Then, welding the TPO edges with a specialized Swiss made machine (Leister 300).

6. Laying vapor Barrier to protect the TPO.

7. Placing a gravel layer (5cm) on the surface.

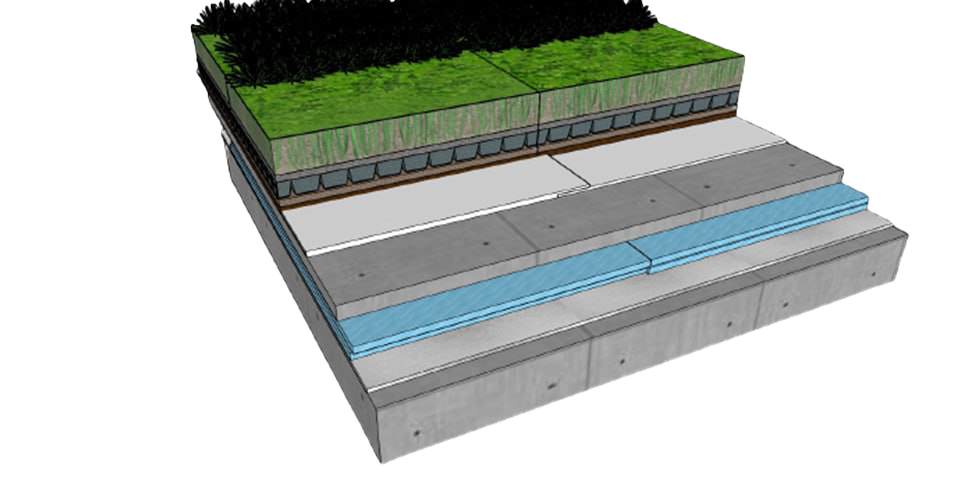

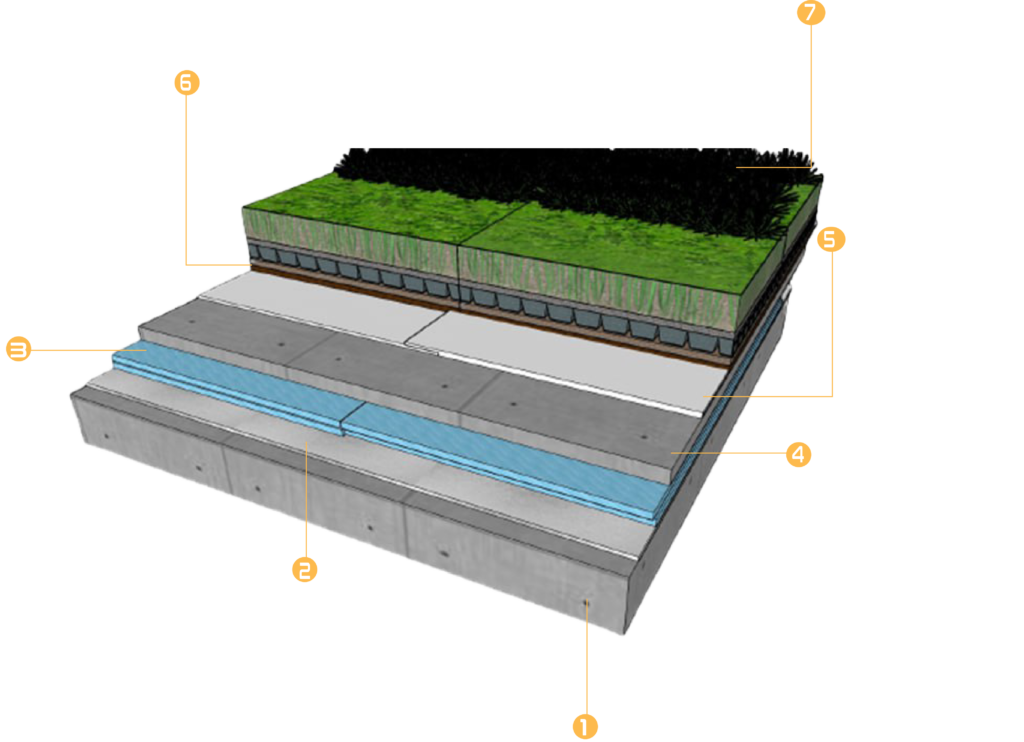

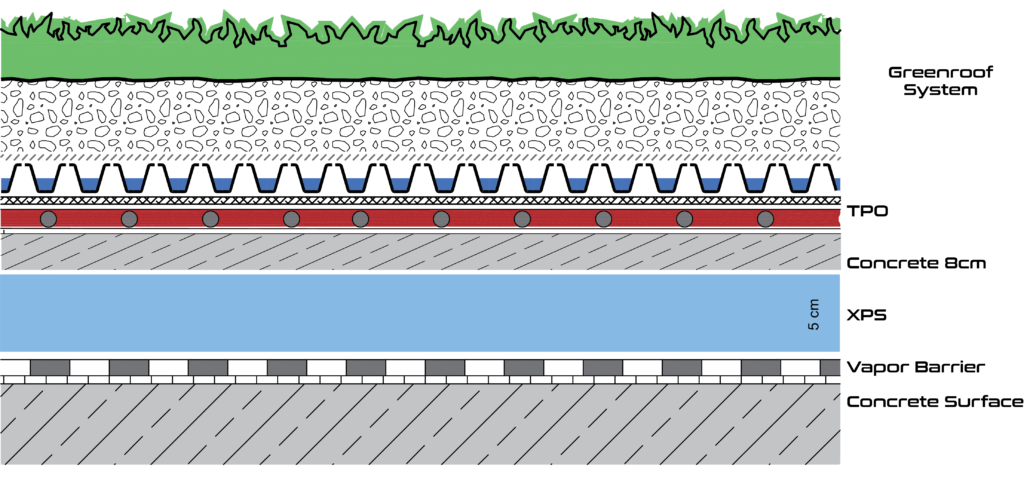

4. Waterproofing, Cold & Heat and Green roof

Procedures

1. Cleaning and grinding the surface.

2. Laying vapor Barrier.

3. Installing one-layer XPS (5cm).

4. Installing 8 cm of concrete layer including BRC iron bars.

5. Firstly, laying the TPO layer on the surface.

6. Then, welding the TPO edges with a specialized Swiss made machine (Leister 300).

7. Laying vapor Barrier to protect the TPO.

8. The roof is ready for Green Roof system.

Materials and Datasheets

Materials and Datasheets

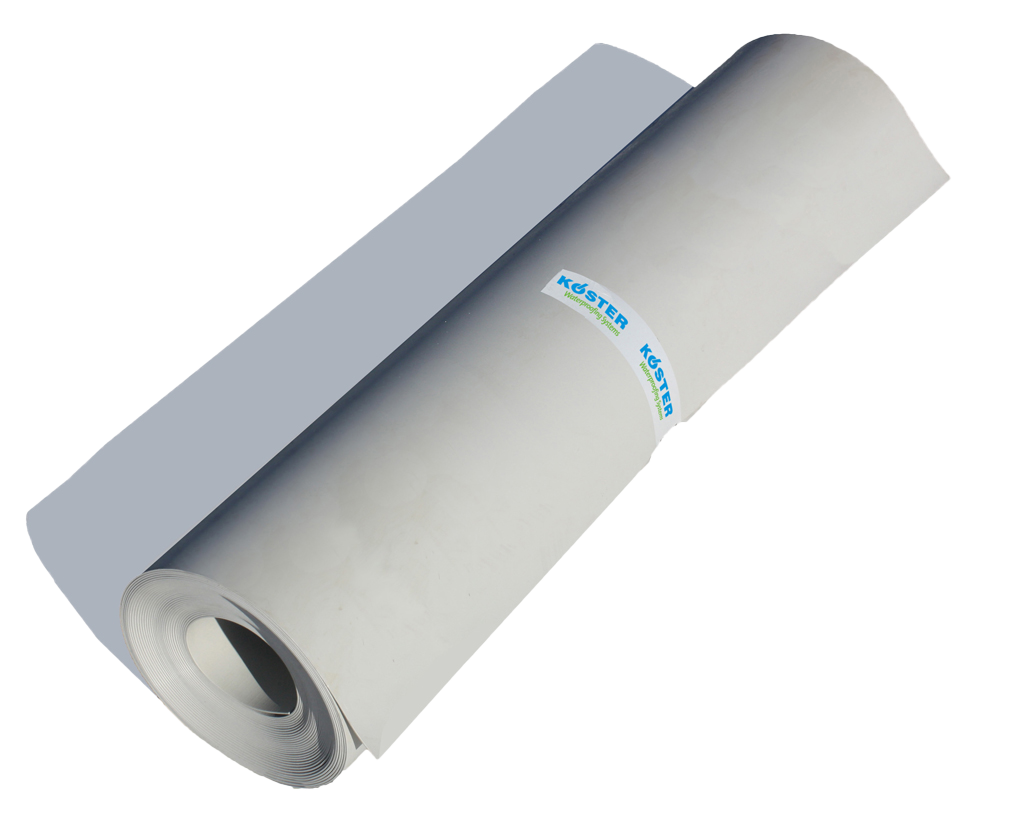

KOSTER TPO Pro 1.8

- Membrane.

- Hot-air-welding plastic roofing.

- Made of thermoplastic polyolefins.

- Can be used for flat roofs, pitched roofs,

green roofs, terraces, balconies, roof

gardens and concrete water tanks. - UV-Resistant.

- Recyclable.

- Safe for health, water, soil, and plants.

- Environmentally friendly.

- High cold flexibility (≤ -50°C).

- Free of softeners and chlorine.

Waterproofing by Using KOSTER NB Elastic Grey:

Layers:

1. Waterproofing wall / floor junctions ( KÖSTER Superfleece ).

2. Primer ( KÖSTER Polysil TG 500).

3. Waterproofing layer ( KOSTER NB Elastic Grey).

4. Reinforcement ( KÖSTER Glass Fiber Mesh).

Procedures:

1. cleaning and griding the substrate.

2. using super fleece for wall and floor junction.

3. Apply koster poly sill TG 500, to consolidate, strengthen, and to protect mineral substrates and to reduce their absorbency and increase adhesion.

4. Apply two layers of KOSTER NB Elastic Grey as a water proofing layer.

5. Using glass fiber mesh between two layers to reduce the danger of cracking.

Materials and Datasheets

Materials and Datasheets

KOSTER Polysil TG 500

- A primer for mineral substrates before waterproofing with cementitious waterproofing slurries for the protection of mineral substrates.

- In case of masonry restoration, the product is used during substrate preparation for restoration plaster systems in order to harden the substrate and immobilize salts.

- KÖSTER Polysil TG 500 is a low viscous.

- substrate solidifying.

- On salt containing and moist substrates.

- it causes a reduction of the pore volume and thereby prevents the renewed formation of salt efflorescence.

KOSTER Glass Fiber Mesh

- Highly tear resistant mesh for the reinforcement of waterproofing layers

- Reduce the danger of cracking as well as connections, wall / floor junctions and fillets.

- Resistant to dislocation.

- plasticizer-free.

- resistant to alkalis.

KOSTER NB Elastic Grey

- Cement base.

- Abrasion resistant

- waterproofing.

- Suitable for moist surfaces.

- Elastic.

- Resistant to foot traffic.

- Suitable for mineral substrates such as

concrete and brick walls. - Can be use for under tile.

KOSTER Superfleece

- High strength polyester nonwoven reinforcement fabric for liquid waterproofing products. To reinforce waterproofing in corners and other areas prone to cracking

- to connect to gutters, gullies, and similar custom details.

- 10 cm and 30 cm wide, 50 m roll.

Waterproofing by Using MS Flexfolie:

Layers:

1. Waterproofing wall / floor junctions ( KÖSTER Superfleece).

2. Primer ( KÖSTER CT 121 ).

3. Waterproofing layer ( KÖSTER MS-Flexfolie ).

Procedures:

1. Cleaning and griding the substrate.

2. Using super fleece for wall and floor junction.

3. Apply koster CT 121, to consolidate, strengthen, and to protect mineral substrates and to reduce their absorbency and increase adhesion.

4. Apply two layers of Koster MS Flexfolie as a water proofing layer.

Materials and Datasheets

Materials and Datasheets

KOSTER CT 121

- KÖSTER CT 121 is a solvent-free primer

- used for priming of mineral surfaces before the application.

- making it exceptionally suitable for filling surface cracks through saturation.

- Suitable for leveling surface roughness before final coating.

KÖSTER MS-Flexfolie

- It is Hybird.

- Single component.

- Solvent free.

- Highly elastic.

- Apply to dry and slightly moist substrates.

- Multiple surface application.

- High UV resistance

- Quickly resistant to rain.

- Eco-Friendly Material.

- Crack bridging waterproofing material.

- Fast curing.

KOSTER Superfleece

- High strength polyester nonwoven reinforcement fabric for liquid waterproofing products. To reinforce waterproofing in corners and other areas prone to cracking

- to connect to gutters, gullies, and similar custom details.

- 10 cm and 30 cm wide, 50 m roll.

Waterproofing by Using XPS:

Expanded Polystyrene, referred to as XPS, it closed cell polystyrene foam, is a form of thermal insulation, the very first foam used for thermal insulation. Commonly used in remodeling and new construction applications.

Procedures:

1. Cleaning and griding the substrate.

2. Using joint tape for the corner of wall and the necessary places.

3. Laying 2 layers of XPS with 10 cm thickness.

4. Placement the concrete 25 mega with BRC and the total thickness is 8 cm.

5. Make the expansion joint for reducing the cracks.

6. Applying koster MS or KOSTER NB Elastic Grey as a water proofing layer.