Water Tank

Water Tank is one of the areas of the building where our company provides Waterproofing services.

Our services include:

1. Supply: We supply the highest German Quality materials of Koster Company. (For details about our Materials Technical Datasheets, please see below)

2. Implementation: Our achievement are supervised by a Certified Engineer of Koster company. They are implemented by Allngar Professional and Experienced Staff.

3. Warranty: Our services warranty long term solutions ( for 25 to 50 years ).

You will save money with us because your Water Tank will not need maintenance in the future.

Our services are perfectly in harmony with modern art on Engineering and they are environmental friendly.

Our company installs the Waterproofing system for Basement wall per the following steps:

Water Tank Waterproofing installment.

Waterproofing water tanks for drinking water (koster TPO Aqua 1.5).

If tile not applying

Water Tank Waterproofing installment.

If tile not applying

Layers:

1. Substructure.

2. KÖSTER TPO Membrane.

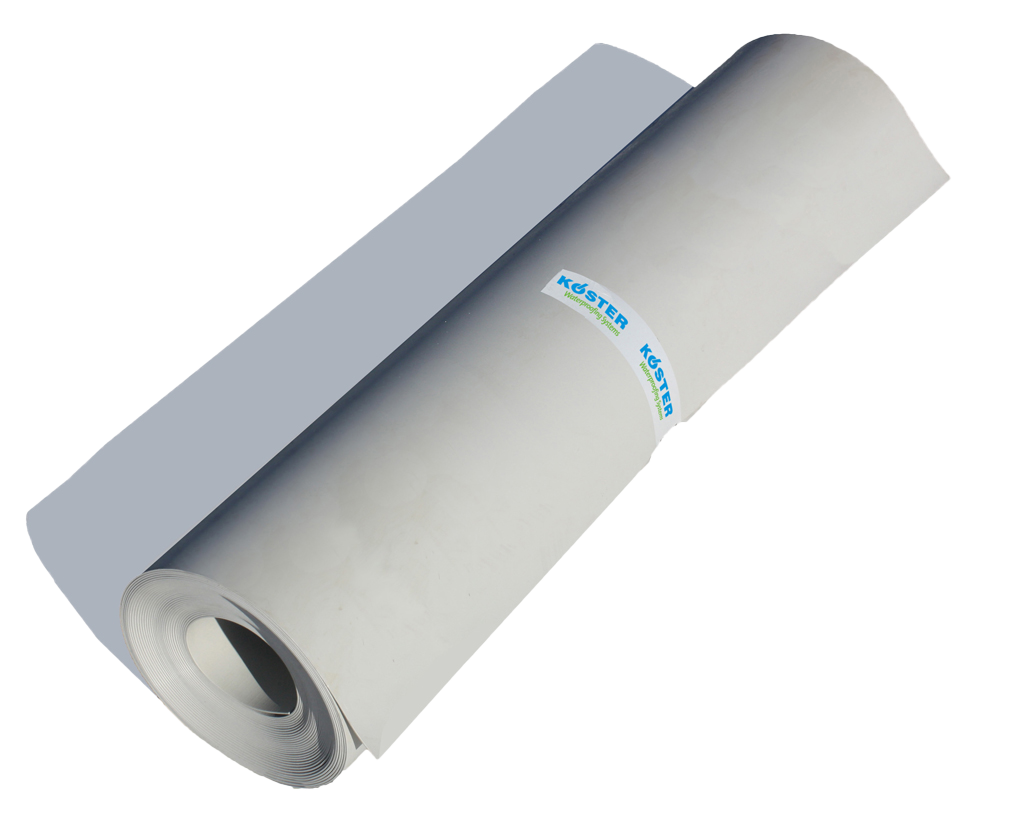

KÖSTER TPO Aqua 1.5 .

3. Mechanical fastening:

KÖSTER TPO Metal Composite Sheet light grey

.

4. Accessories

Leister Automatic Welder Uniroof 300.

Procedures:

1. Cleaning and griding for the substrate.

2. Laying TPO .

3. Using Leister Automatic Welder Uniroof 300 for welding.

Materials and Datasheets

Materials and Datasheets

KÖSTER TPO Metal Composite Sheet Grey

One-sided TPO coated zinc plated metal sheet used to fabricate metal

drip edges and other roofing edge profiles.

KÖSTER TPO Aqua 1.5

- it is a membrane.

- highly tear resistant.

- provides very high flexibility.

- large cracks are securely bridged.

- Environmentally friendly.

- Hot air welding plastic roofing.

- UV Resistance.

- Recyclable.

- Safe for health, water, soil and plant.

Water Tank Waterproofing installment.

Waterproofing water tanks (KOSTER NB Elastic Grey). If not using for drinking water.

Waterproofing water tanks with 2 component elastic mineral coat

Water Tank Waterproofing installment.

Layers:

1. And 2. (Concrete Repair and Installing fillets) : KÖSTER Repair Mortar Plus

.

2. Primier: KÖSTER Polysil TG 500

.

3. Waterproofing Layer: KOSTER NB Elastic Grey.

Procedures:

1. Cleaning and griding for the substrate.

2. Using Koster repair mortar plus for the installation of fillets.

3. Apply Koster poly sill TG 500to consolidate, strengthen, and to protect mineral substrates and to reduce their absorbency and increase adhesion.

4. Apply two layers of KOSTER NB Elastic Grey as a water proofing layer.

5. Using Glass Fiber Mesh between the two layers to reduce the danger of cracking.

Materials and Datasheets

Materials and Datasheets

KÖSTER Repair Mortar Plus

- Hydrophobic and water proofing.

- fast setting repair mortar which is resistant to pressurized water.

- slightly expanding repair mortar with excellent adhesion

- it can be used as a PCC (polymermodified cement concrete) mortar.

KÖSTER Polysil TG 500

- A primer for mineral substrates before waterproofing with cementitious waterproofing slurries for the protection of mineral substrates.

- In case of masonry restoration, the product is used during substrate preparation for restoration plaster systems in order to harden the substrate and immobilize salts.

- KÖSTER Polysil TG 500 is a low viscous.

- substrate solidifying.

- On salt containing and moist substrates.

- it causes a reduction of the pore volume and thereby prevents the renewed formation of salt efflorescence.

KOSTER NB Elastic Grey

- Cement base.

- Abrasion resistant

- waterproofing.

- Suitable for moist surfaces.

- Elastic.

- Resistant to foot traffic.

- Suitable for mineral substrates such as

concrete and brick walls. - Can be use for under tile.