Crack Injection is one of the areas of the building where our company provides Waterproofing services.

Our services include:

1. Supply: We supply the highest German Quality materials of Koster Company. (For details about our Materials Technical Datasheets, please see below)

2. Implementation: Our achievement are supervised by a Certified Engineer of Koster company. They are implemented by Allngar Professional and Experienced Staff.

3. Warranty: Our services warranty long term solutions ( for 25 to 50 years ).

You will save money with us because your Crack Injection will not need maintenance in the future.

Our services are perfectly in harmony with modern art on Engineering and they are environmental friendly.

Our company installs the Waterproofing system for Basement wall per the following steps:

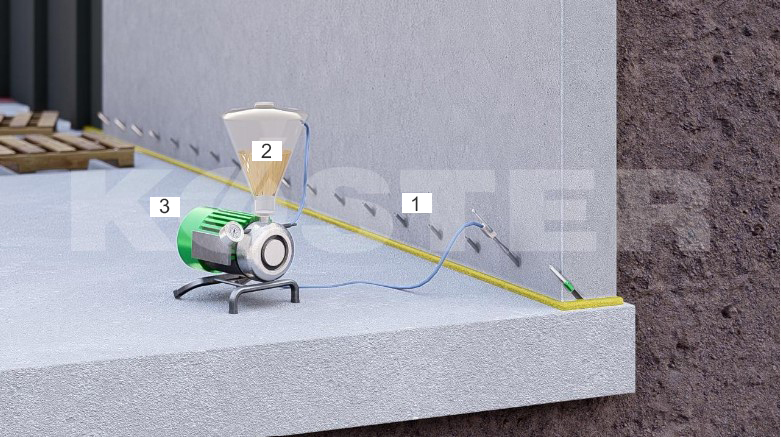

1. Installing the packers.

2. Injection Resin: Koster 2 IN 1 or Koster IN 8 .

3. Pump: KÖSTER 1C Injection Pump.

1. Filling up wall cracks by Koster repair mortar plus.

2. The wall is drilled with an angle of 45 degree from both sides.

3. The injection valves known as a Packers are installed into the 45-degree angle drilled holes.

4. The material of injection koster 2 IN 1 or Koster IN 8 is sealed through the packers to fill up all the cracks in the wall.

Allngar Company provides and distributes different products of the German isolation (water, cold and heat) and to implement the engineering project.

Allngar Co. is dedicated to providing German quality construction materials, technical and practical.

Read more© Allngar Company 2022. All rights reserved.